Moyno

Moyno, Inc. is a global leader in the design and development of the progressing cavity pump. Its technological advancements have resulted in superior fluids handling solutions for a wide range of applications including water-like liquids and shear-sensitive fluids, as well as viscous, abrasive, solids-laden slurries and sludges.

Pump Trac Ltd. is in no way indicating we are supplying OEM parts or an authorized distributor.

We carry the following:

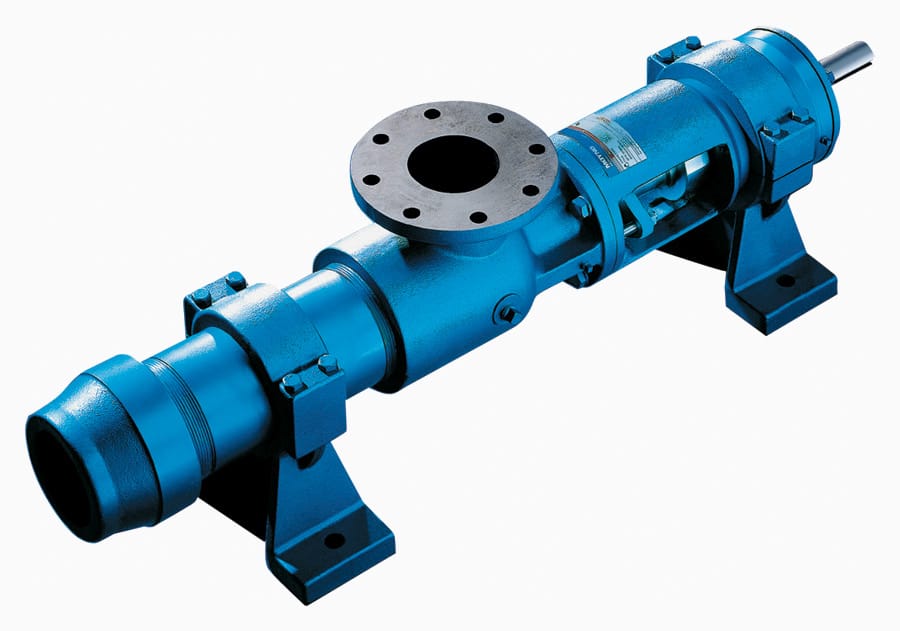

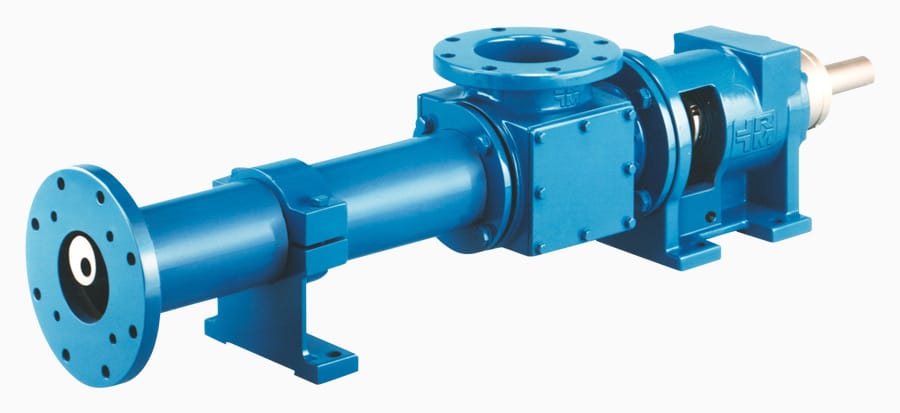

Moyno L-Frame Pumps

For nearly 50 years, versatile Moyno L-Frame pumps have stood the test of time meeting thousands of application challenges with performance-enhancing, cost-saving features.

Features

- Low total cost of ownership

- Simple pin-type universal joint drive assembly for easy maintenance

- Application versatility, modular design and wide selection of materials of construction

- Steady flow under wide NPSH variations

- Variety of Ultra-Shield® rotor coatings and Ultra-Flex® stator elastomers

- Open suction hopper and bridge breaker models available

Performance Features

- Non-pulsating

- Low shear, accurate, repeatable flow

- Viscosities to 1,000,000 cps

- Handles solids to 1" in diameter

- Pressures to 2,100 psi; capacities from .02 to 450 gpm

Typical Applications

- moyno l frame pumps

- High-pressure water

- Pastes & gels

- Food, wastes & by-products

- Chemical feed & sampling

- Coolants & lubricants

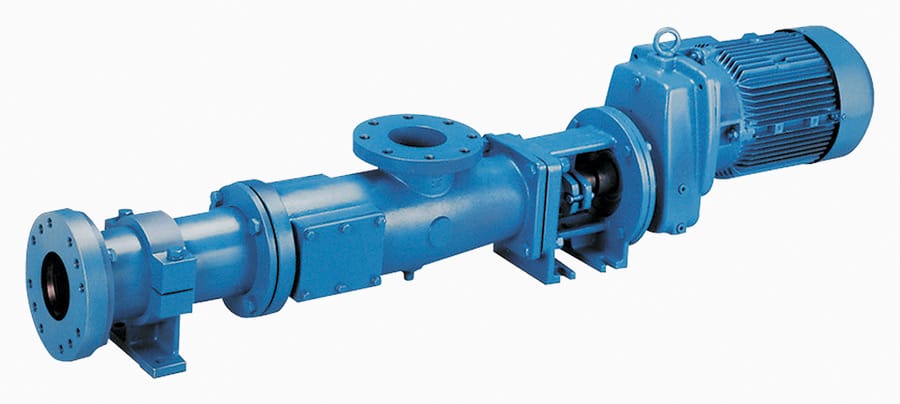

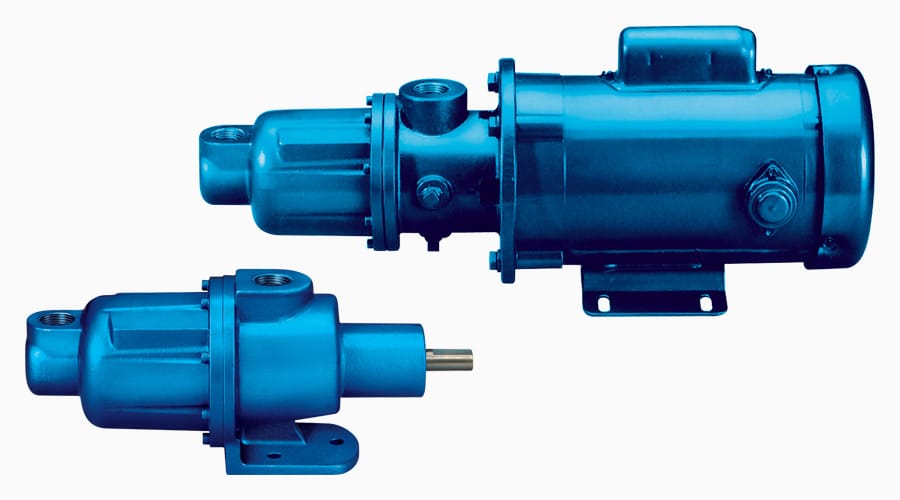

Moyno 1000 Pumps

Economical, high-efficiency Moyno 1000 pumps offer an unparalleled combination of features other positive displacement pumps cannot match.

Features

- Low-maintenance drive trains with sealed and lubricated pin-type universal joint for extended service life

- Two-piece shaft design allows easy mechanical seal and pump maintenance

- Standard flange, close-coupled and open throat hopper models

- Highest grade components include Ultra-Shield® rotor coatings and Ultra-Flex® stator elastomers on all models

Performance Features

- 1000 cut

- Low NPSH requirement

- Non-pulsating

- Low shear, accurate, repeatable flow

- Viscosities to 1,000,000 cps

- Handles solids to 1.1" in diameter

- Pressures to 350 psi; capacities from .02 to 345 gpm

Typical Applications

- Chemical dosing & transfer

- Polymer metering

- Adhesives & mastics

- Oily water separation

Moyno 2000 Pumps

Moyno 2000 pumps set the standard in positive displacement pumping applications. The proprietary Moyno 2000 gear-type universal joint design effectively handles radial and thrust loads for maximum performance and long life.

These rugged pumps are able to handle abrasive materials in excess of 80% solids and offer a performance range to 4,500 GPM with pressure to 1,500 PSI.

|

|

2000WA - Close Coupled DesignFeatures intergral shaft bearings specifically designed for applications that require the transfer of highly viscous fluids and solids where a close coupled configuration is preferred, but the robustness of a gear joint is desired |

|

|

2000WB - Close Coupled DesignTraditional close coupled pump specifically designed for applications that require the transfer of highly viscous fluids and solids where a close coupled configuration is preferred, but the robustness of a gear joint is desired |

|

|

G1 - Flanged DesignVersatile, high performance pump designed to handle a wide range of applications from shear-sensitive chemicals to difficult-to-process slurries and sludges |

|

|

G2 - Single Auger FeedVersatile, high-performance pump featuring a wide, open throat hopper design that minimizes plugging that could occur in a standard inlet |

|

|

G3 - Bridge BreakerSuited for handling semi-dry, high solids content fluids that have a tendency to "bridge" in the inlet hopper |

|

|

G4 - 45 Inlet Design45 degree inlet lowers friction loss and provides for gentler handling of the product |

Moyno 500 Pumps

General purpose Moyno 500 pumps handle thousands of applications from clean, clear liquids to abrasive and corrosive fluids. There are over 70 Moyno 500 models available in a variety of materials of construction with many different options to allow customization to meet specific application needs.

The new Moyno Mag Drive 500 Series pumps feature a patented sealless, magnetic drive design that provides zero leakage for the most critical applications. This proprietary progressing cavity mag drive pump utilizes the latest technology to ensure operator safety, eliminate work place hazard and protect the environment from contamination. The mag drive 500 pump uses a nagnetic coupling to establish a static seal, aligning an outer drive magnet with an inner driven magnet within a stationary containment shell. The resulting sealless design not only performs well in hazardous applications but is also effective with difficult to seal fluids. Skid mounted, turnkey systems are available for one-stop, hassle-free shopping that saves time and money.

Features

- Compact and lightweight design for installation flexibility

- Motorized and non-motorized models ideal for OEM applications

- Self-priming

- Quiet operation

- Low maintenance

- Mag Drive 500 series uses a patented, sealless technology to provide zero leakage

- Performance Features

- Positive Displacement

- Non-pulsating

- Low shear, accurate, repeatable flow

- Temperature range to 240° F

- Pressures to 600 psi; capacities from .02 to 66 gpm for standard models

- Pressures to 75 psi; capacities from .01 to 900 gph for Mag Drive 500 Series models

Typical Applications

Standard Models:

- Abrasive chemicals & slurries

- Marine septic systems

- Nitric acid

- Paints & Inks

- Laboratory testing

Sealless Mag Drive 500 Series Models:

- Sodium Hypochlorite

- Ammonia

- Hydrogen Peroxide

- Ferric Chloride

- Aluminum Chloride

- Ammonium Chloride

- Calcium Chloride

- Nickel Chloride

Moyno Tri-Phaze

The multiphase fluid produced from many oil and gas wells is composed of varying ratios of oil, water, gas and in many cases, small amounts of sand and paraffin. Traditional multiphase fluid transfer involves the use of separation equipment and compressors at the wellsite or satellite to separate the oil, water and gas. The gas can be flared off and the separated fluids are then transferred via multiple pipelines, barges or trucks to a central processing station.

An older well is likely to have a gas volume fraction (GVF) which has increased over the years causing production to become marginal. The costs to install, operate and maintain the traditional multiphase fluid transfer equipment may not be justified by the production from the well or field.

Recently, efforts have been made to develop pumps capable of handling multiphase fluids. However, results indicate that most types of pumps are restricted by their inability to automatically adjust to rapidly fluctuating gas-to-liquid ratios. They can't handle sand or other solids in suspension or efficiently pump fluids with varying API gravities. Many have a tendency to emulsify the fluid making separation much more difficult.

Prompted by a market need for a more efficient multiphase fluid transfer solution, Moyno, Inc. developed the breakthrough Moyno Tri-Phaze® System. Its patented progressing cavity design effectively pumps oil, gas and water from the wellsite or satellite through a single pipeline to a remote processing station without degradation or emulsification of the fluids. It effectively transfers multiphase flows up to 80,000 BPD and differential pressures up to 1,350 psi.

The progressing cavity design consists of a single-threaded, external helix (rotor) turning within a double-threaded internal helix (stator). As the rotor turns within the stator, cavities are formed that progress from the suction to the discharge end of the pump. The fluid flows in a spiral path through the pump not far removed from a straight line. The resulting low shear pumping action will not emulsify the oil and water phases, therefore making separation easier at the processing station.

By significantly lowering wellhead pressures, the Moyno Tri-Phaze System has been proven to increase production of even marginal wells. Furthermore, it can handle high gas volume fractions, high sand percent, aromatics, changes in API gravity, and H2S gas.

Features

- Uses a small electric motor that operates at slower speeds

- The patented design handles high gas volume fractions without premature breakdown of the stator due to excessive heat build-up.

- When compared to a new battery installation for a new or exisiting formation, the Moyno Tri-Phaze System costs less to install, maintain and operate, and is environmentally friendly.